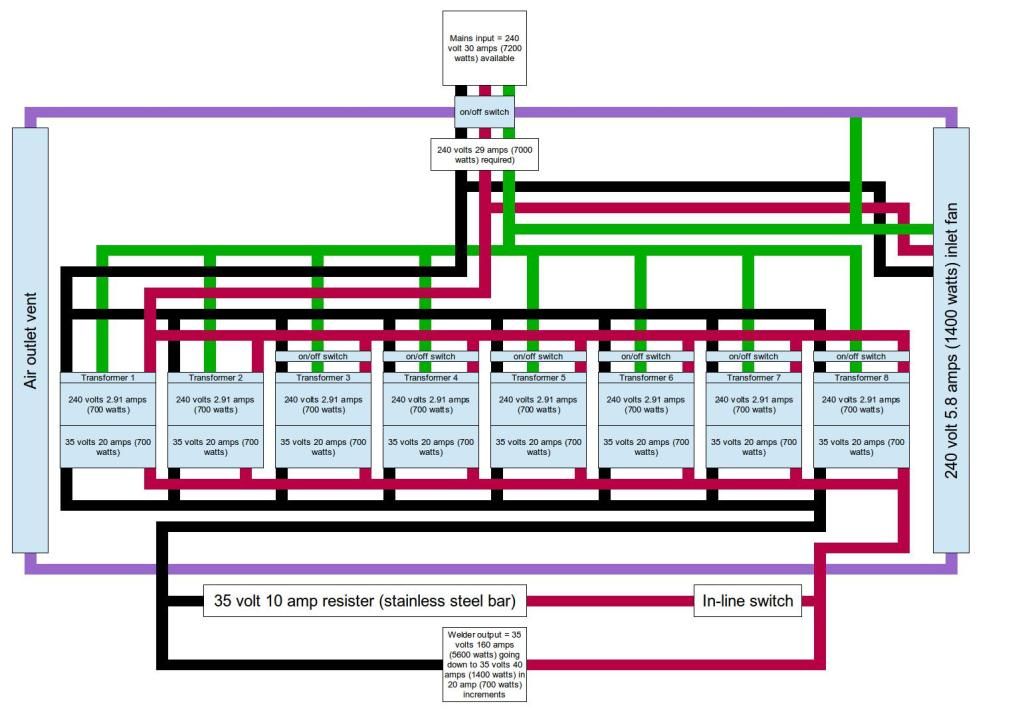

The purple line is the transformer case. The red, black and green lines are positive, negative and earth wires respectively (yes, I know there is no such thing as "positive" and "negative" on AC....

My reason for wiring the seondaries in parallel is that it allows me to have relatively high-voltage/low-amperage on each transformer secondary. This, in turn, allows me to use more readily available/scavengeable 30-amp single-core wire. Being of relatively small diameter, I should, be able to get 35 winds on the secondaries (it's approximately 1 volt per turn). I can then pump the amperage up via wiring the secondaries in parallel. The other advantage of having relatively low amps coming out of each individual secondary is that it keeps the heat down on them. It means I have more weight because of having to use more transformers to achieve the necessary welding amps. But, that's not an issue. Finally, wiring the secondaries in parallel allows me to individually switch them off and so adjust welding amperage. I should also say, as I understand it, these transformers have shunts in them to limit the through-put to 700 watts. So, there should be no risk of runaway amperage demand at the welder end.

The parallell resister on the welding output side can be switched on or off to allow for 10-amp sub-incremenets on the welding amperage. I understand, though, that it is important to make sure this is switched off immediately when there is no actual welding load as the full amperage would then pass through this resister making it get very hot in short order.

I haven't got anywhere near building this yet. Indeed, I may never build it. It's just a mental exercise really.